Let’s take a closer look at our machine with artificial vision for the quality control of filters for coffee capsules. In the images we can appreciate the automation of sorting the capsules, which are taken to the control area. The star-shaped component subdivides them and makes them advance to the camera, which acquires the image of the product in transit, analyzing its dimensional characteristics. The machine then discards the defective capsules, using a nozzle that blows them into a side tube. The capsules with the correct dimensions are instead sent to the next stage of production.

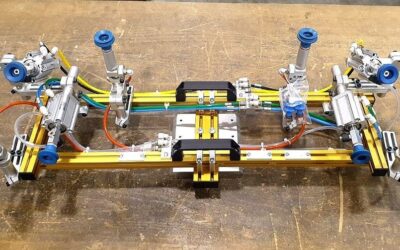

Improvements for our GZA class grippers

"Improvements are on the horizon for our GZA class grippers. These technical enhancements focus on achieving perfection through the integration of new miniaturized sensors, reducing the size of the grip fingers and incorporating non-detachable rotation pins. Giuseppe...