“We at FPS Automation will continue to represent the innovation. We are not interested in becoming one of the many rigid companies with no more ideas in our sector. We want to win with passion all the challenges posed to us by the world of molding. When I hire a person, I want to see his eyes shine, because I know that he will be able to follow me and express the full potential of competence, creativity and courage that successfully distinguishes my company”. These are the words of our founder, mr. Fabrizio Peppi, who in recent months pushed on the accelerator of renewal, making significant investments in the improvement of processes and, above all, in new and motivated professional resources, some of which come directly from competitors.

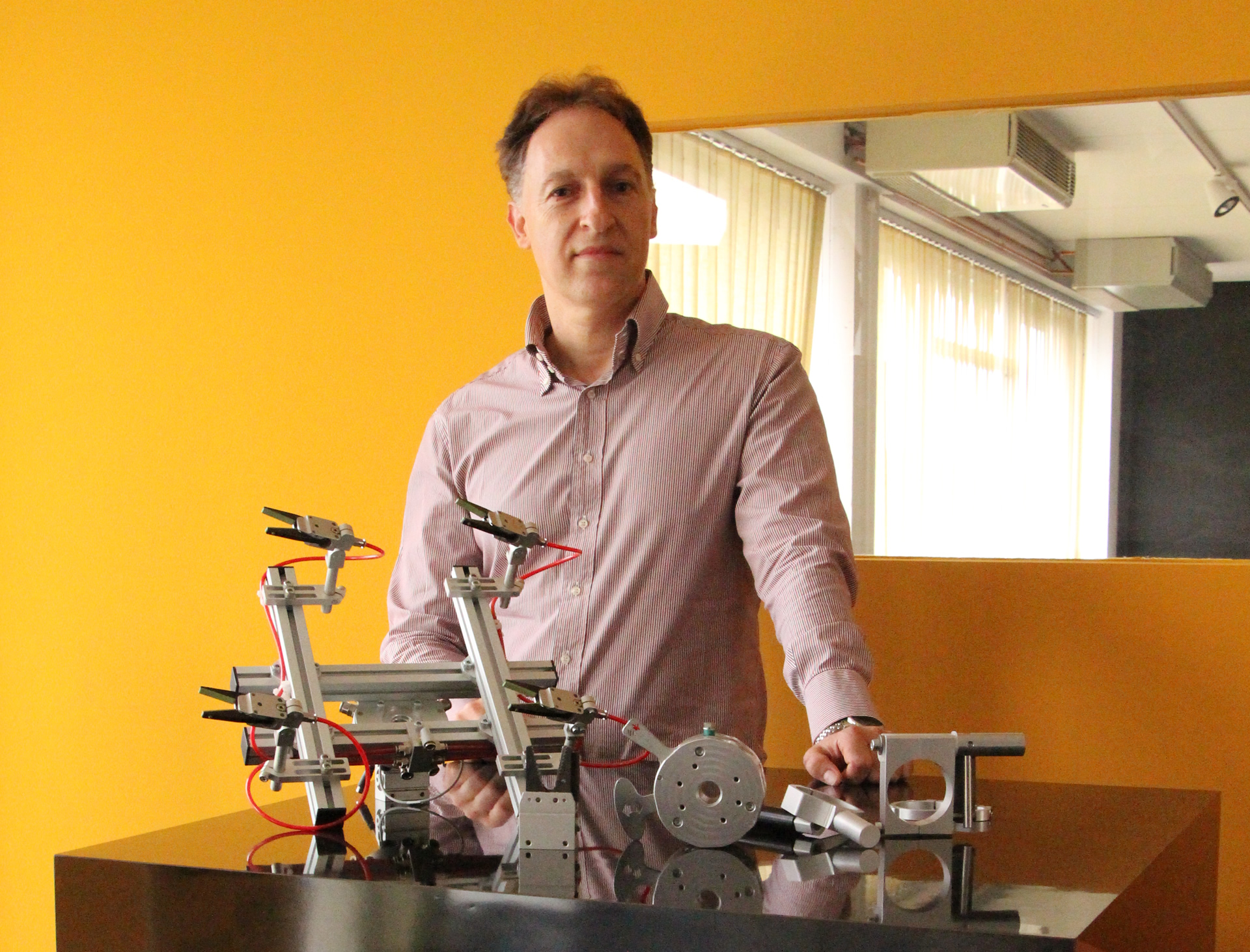

The new Purchasing and production planning manager.

After the entry into the company of mr. Paolo Vanini (Operation and internal sales manager) and mr. Giuseppe Cardovino (Commercial Director), it is now the turn of Luciano Giancola, a graduate in mechanical engineering with a specialization in Production, with the task of Purchasing and production planning manager.

Luciano Giancola, from the middle-italian Region Abruzzo, moved to Emilia Romagna after the terrible earthquake of 2009, due to the severe blow suffered by the industrial fabric of his town Aquila, since then he has been involved in the organization of production and purchase management. His background will be particularly appreciated in the industrialization phase of the standard FPS product.

“I have been in FPS for a few weeks – says mr. Giancola – and at the moment I am dealing with the automations in which the state of the work is already in an advanced phase, then I will dedicate myself instead to standard production, which I will have to organize on the basis of the new company protocols. prepared by the Management. The climate I found in the company is excellent – he concludes -, I was very well received and I found great availability and proactive colleagues. All the conditions are in place to better face this new professional challenge and improve the performance of the production process”.